March 22nd, 2021 Sahil Graphics

Offset printing is a widely used commercial printing technique used for the printing of a wide range of products like cards, leaflets, books, magazines, and more. Also known as offset lithography, this printing process is also used for labeling packages like cartons and boxes.

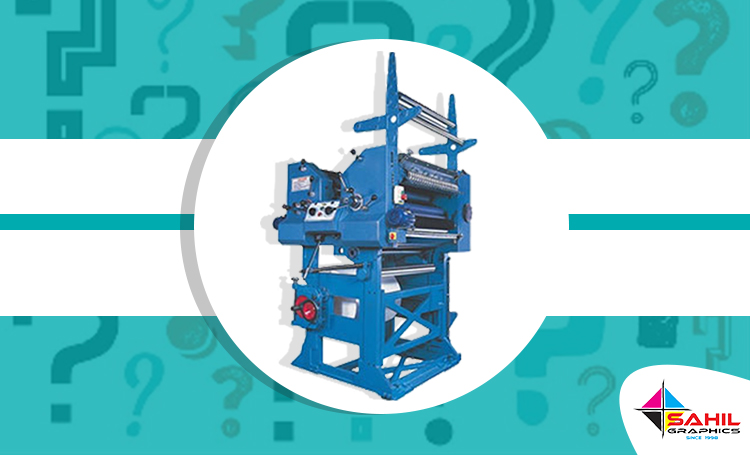

This printing technique is called as ‘offset’ because it doesn’t transfer ink directly to the paper unlike other printing methods do. This printing technique is used widely in which the inked image is printed on the rubber cylinder and then further transferred or offset to any paper or other material. The rubber cylinder used in offset printing machine gives greater flexibility as it permits printing on cloth, wood, leather, rubber, and any rough paper.

An offset printer involves three cylinders including:

In this kind of printing process, the image and non-image areas co-exist on the same surface. This means that the surface from which you print will be flat.

The first cylinder i.e. plate cylinder is a thin cylinder that has a plastic or aluminum plate around it. Each plate in this cylinder is customized according to the images and text to be printed onto the paper. The plate cylinder used in an offset printing machine is pre-treated to have images attract ink and then repel water. Whenever this cylinder spins, it makes contact with the rollers which apply ink and water.

Another cylinder used in this printing machine is the offset blanket cylinder. Usually, this cylinder has a rubber blanket around it and turns in the opposite direction of the first cylinder. When the plate and offset blanket cylinder rotates against each other, water is squeezed away and ink is transferred onto the rubber blanket. This part creates a mirror image of the ink design.

The offset impression cylinder is made up of clean steel, and it turns in the opposite direction of the blanket cylinder. This cylinder transfers the ink as it presses against the rubber blanket. This is a very fast and efficient process that may print around 20,000 sheets in an hour.

Here are the key benefits of offset printing:

It is always important to choose a well-known and reputed printing company to fulfill offset printing requirements. Expertise is important in this field for obtaining a good quality product within the given time frame.

Ask Our Experts