February 22nd, 2022 Sahil Graphics

Plastic bags, especially those made of polyethylene, have a negative impact on the environment because they are not biodegradable, which is the main cause of soil and water pollution. They are also dangerous for wildlife, as cows and marine animals tend to eat plastic bags that they cannot digest, which eventually lead to their death. The ban on single-use plastic products in India, which comes into effect on October 2, 2019, has increased the demand and popularity of paper bags to a great extent.

Paper bags are eco-friendly as they can be easily recycled. With consumers becoming more aware of eco-friendly options, paper bags have become the best choice. Paper bags are manufactured in two ways, namely by hand or with the help of paper bag manufacturing machines. Making Vbottom paper bags with the help of V Bottom Paper Bag Making Machine has various advantages, some of which are described below

If you want to invest in a paper bag manufacturing company, then this is a good option to begin with, because the demand for paper bags is increasing significantly after the ban on plastic bags. You may have noticed that all the big brands in retail, FMCG sector, restaurants, etc. are now using paper bags.

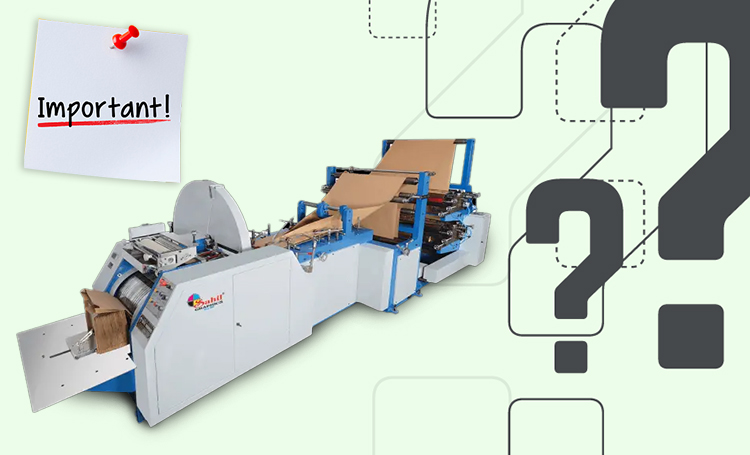

This shows that paper bags will be around for a long time. So before you invest in this business, you should focus on one important point: buying a fully automatic V Bottom Paper Bag Making Machine from the right supplier.

Sahil Graphics is one of the prominent manufacturers and exporters of a range of paper bag making machines. If you are in need of a V Bottom Paper Bag Making Machine, then wait no longer and contact Sahil Graphics to purchase the machine that will help you produce quality paper bags.

The machine is designed to produce Sharp V-Type Bottom Paper Bags and comes with an additional feature of 2 color printing On-Line and increased the maximum bag width upto 350mm.

Ask Our Experts