The P 1200 Paper Plate Making Machine features a heavy, sturdy frame for durability. It operates at a speed of 90-120 pcs/min, handling materials from 180-500 GSM. With a PLC control panel and hydraulic pressure of 8 tons, it ensures reliable and efficient operation. The double station workstation and robust construction make it ideal for high-quality paper plate production.

Sample Plate

Detailed specifications

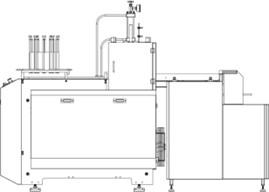

Mechanical drawing: 500Y is the newest design which is popular in domestic and abroad. Machine with steady body frame which is constructed by 2cm thickness iron plate, looks more strong and professional, other factory using welding frame

Paper feeding section: The paper feeder parts is controlled by the suction part which need support by air compressor, process the paper products to the conveying parts steady and orderly.

Perfect for paper with or without PE coating.

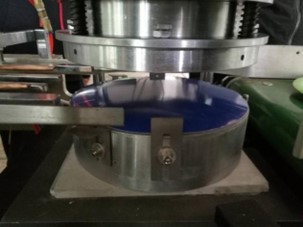

Paper molding section: The paper products will be delivered into the mold section (up and lower mold) which is controlled by PLC, it is detected by two Photoelectric sensors, after molding, two air pipe will blow the plate off the mold.

Hydraulic sections: Two fast hydraulic working sections with 5 tons pressure, 15cm working distance, need lubrication oil to cycles. Paper size around 11 inch. With one fan to freeze and 7.5kw motor to cycle the lubrication oil when working.

Electrical parts: Machine is controlled by PLC, with mold heating, Photoelectric sensors, touch screen. Custom designed electrical parts is available.

Machine frame:

Constructed by 2cm and 2 pieces iron plate fixed by plain shafts which is more steady than the welding frame, can be serve for a long time.

| S no | Model | |||

|---|---|---|---|---|

| 1 | Frame | Heavy Sturdy Frame | ||

| 2 | Production Speed | 90-120 Pcs/Min | ||

| 3 | Suitable Material | 180-500 GSM | ||

| 4 | Black Paper Size | 7-14" (180-350MM) | ||

| 5 | Total Power | 12KW | ||

| 6 | Weight | 1600 Kg | ||

| 7 | Dimension | 2600x1170x2000 MM | ||

| 8 | Control | PLC Control Panel | ||

| 9 | Pressure | Hydraulic-8 ton | ||

| 10 | Power Source | 3 Phase-380V,50Hz | ||

| 11 | Work Station | Double Station |