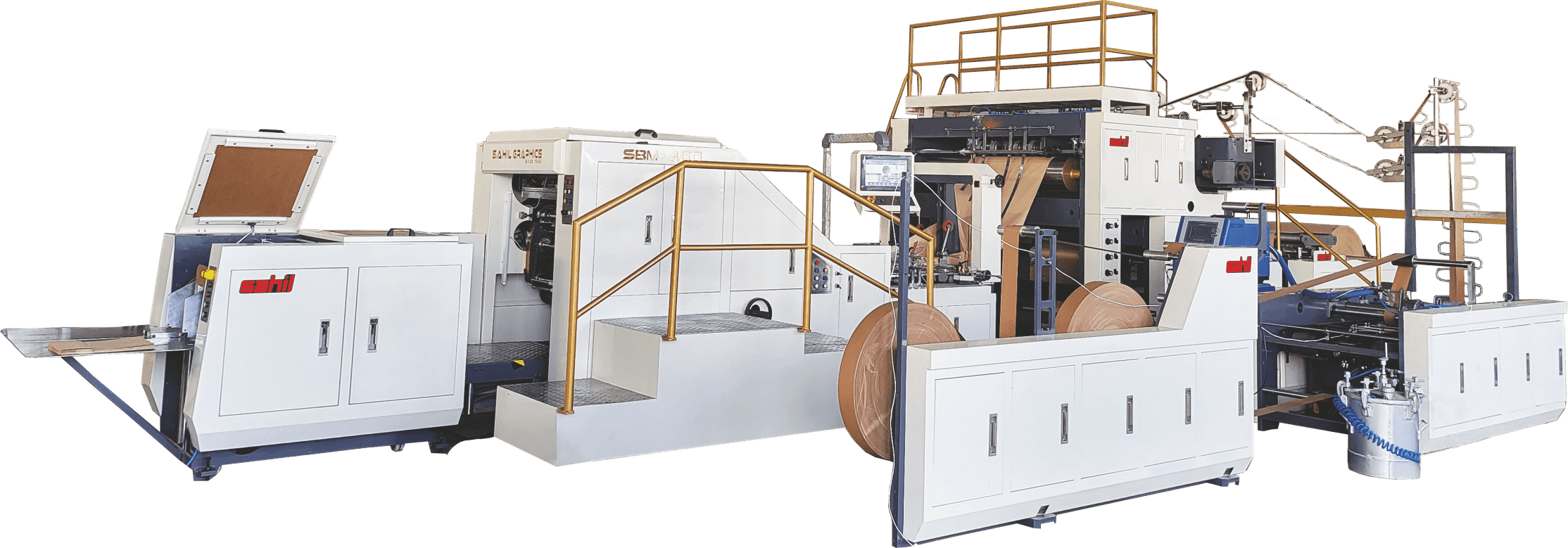

Square Bottom Paper Bag Making Machine (SBM-360/SBM-460)

Sahil Graphics is known to producing and manufacturing paper bag machines which are highly innovative and offers a great deal of advanced features which make them stand apart from the rest. One such outstanding Square bottom paper bag making machine is available in the market which comes with various useful configurations which have been summarized below-

- Numerous wide bag size range

- High Performance

- Durability

- Easy Operations

- Automation that reduces overall wastage

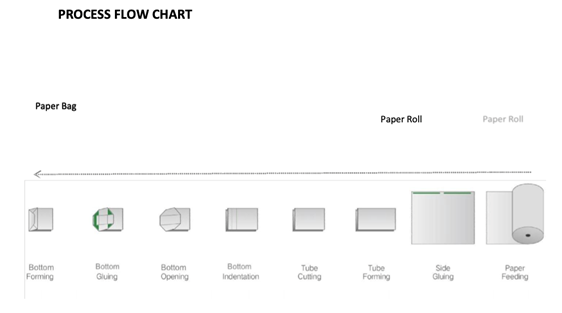

PROCESS FLOW CHART

MACHINE PARTS

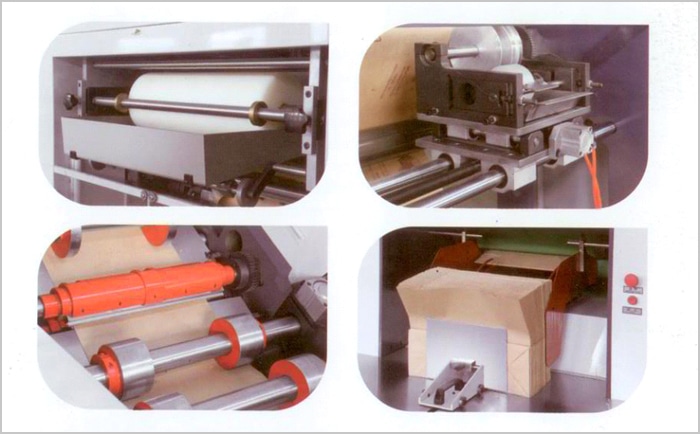

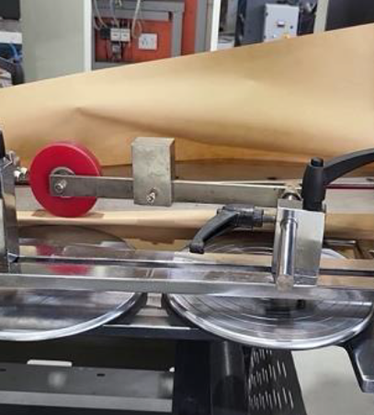

Part 1 Reel Feeding Unit

- Lifting the heavy reels is a major concern, now with reel feeding that is equipped with an automatic hydraulic lifting function; it is possible to get the task done with the mere click of a button.

There is a need for heavy brakes to support the tension required for handling the paper in the entire reel cycle, thanks to an appropriate automatic tension control system, this process can be done with ease.

2. The machine is further equipped with an automatic edge correction system that is designed to form the tube in perfect shape without any kind of wastage.

Well, it is important to glue the paper in a proper manner, with an automatic side glue dispensing system, the exact amount of glue is put according to the different quality of the paper. The exact glue is dispensed considering the speed of the running paper.

Part 2 Paper bag forming unit

- This is the part where maximum operations are done. It starts with Tube forming side pasting bag, creasing the bottom, gluing the bottom.

- There are two servo motors present which ensures the right cutting. The perfect cut can be changed and achieved through the touch screen.

- The machine is completely stable and provides exceptional performance thanks to the strong and flexible mechanical components used.

- The machine is so designed with heavy duty, that it is able to handle high stress and is capable of working round the clock.

- To reduce the overall chances of breakdown, auto detection electric sensors have been installed in the unit.

Part 3 Machine Material

| Tube former material | Stainless steel |

| Shaft material | EN 8 hard chromed |

| CAMS materials | EN24 , EN31 |

| Roller | Anodized aluminum , stainless steel |

| Cutter roller assembly | Dynamically balanced |

| Central drum | Assembly Dynamically balanced |

| Lubrication | Centralized automatic cooling |

Part 4 Finished bag collection unit

Here, the formed paper bags are completely pressed and conveyed out of the belt. The bag collection unit gets the data from the plc and a large number of stack bag are manufactured in the required quantity.

- Automatic detection of the electric eyes

- Automatic counting of thr photo eye

Part 5 Machine Electrical panel

It is understood that the electric panel of the machine is the brain of the machine. There are several high quality components that have been designed to deliver high performace without any delay. With safety devices, the machine is safe and is not easily damaged. Various components of the machine have been mentioned below:

Automatic fault detection function

Well, as the name suggests the main function of this unit is to protect the machine when it is running at a normal high speed state, and any kind of unexpected errors occurs. In this case, the machine automatically stops to avoid any kind of unnecessary losses. This device is based on and works in conjugation with the Japanese Yaskawa automation control system.

Automatic refueling system

This system is designed to supply oil to the machine while it is running. This system makes sure that all the parts of the machine and gears are completely lubricated, and the machine can work hassle free without any lag in performance even on long-term use.

Machine Advantages

Widest Bag Size Range: It is possible to get the bags of various size ranges. With the latest design structure, there is no need to buy machines of two different sizes as one can get a wide range in a single machine itself.

Hydraulic lift: Loading the material was never so easy and the hydraulic automatic lifting structure makes the tasks all more simpler and faster. There is an automatic tension control system for better operation.

Servo Motor control system: This system is an electronic control system that has been imported from Japan and ensures stability and high-speed operation. The high accuracy is achieved through two servo motors.

Automatic Glue Dispensing: Automatic glue dispensing unit makes sure that the right amount of glue is put in according to the quality of the paper. It is also possible to change the dispensing speed according to the flow speed of the paper.

Dual Plate technology: The forming template comes with an adjustable double template structure which makes it easier for the user to design paper bags of different sizes without the need to change the template. This effectively reduces the time lost in adjusting the paper bag size and thus increases the machine capacity.

Automatic Web Guide: There is an automatic correction unit that is designed to reduce the overall material alignment time.

High Quality Materials: All the components used in the machine are of high quality and ensure that the machine gives the best performance with high stability.

Connect Now!

Machine Specifications

| S no | Model | SBM-360 | SBM-460 | |

|---|---|---|---|---|

| 1 | Cutting Length | 270-530mm | 270-530mm | |

| 2 | Paper Bag Width | 140-360mm | 230-450mm | |

| 3 | Bottom Width | 80-180mm | 100-200mm | |

| 4 | Paper Bag Thickness | 60-150g/m2 ² | 60-150g/m2 | |

| 5 | Paper Bag Speed | 30-200pcs/min | 30-200pcs/min | |

| 6 | Paper Roll Width | 480-1050mm | 690-1300mm | |

| 7 | Paper Diameter | 1300mm | 1300mm | |

| 8 | Inner Diameter of Paper | 76mm | 76mm | |

| 9 | Power (3 Phase) | 15kw | 15kw | |

| 10 | Weight (Approx.) | 8500kg | 10000kg | |

| 11 | Dimensions (Approx.) | 10000*3700*2200mm | 10000*3800*2200mm |