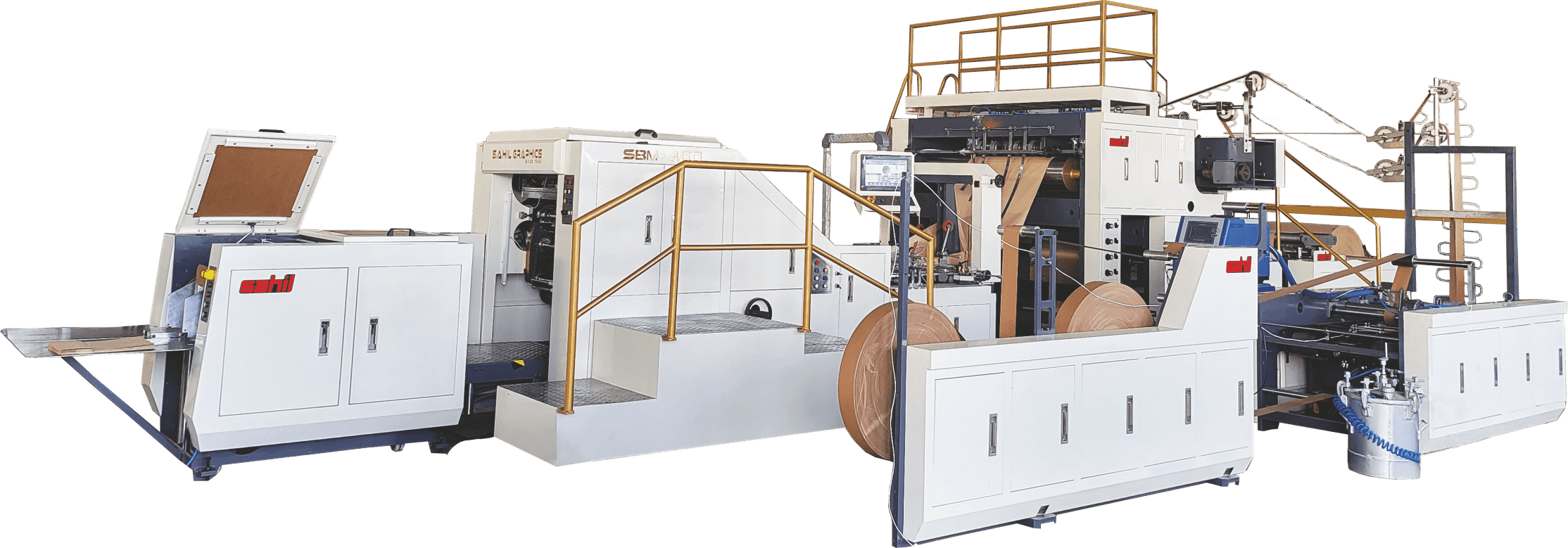

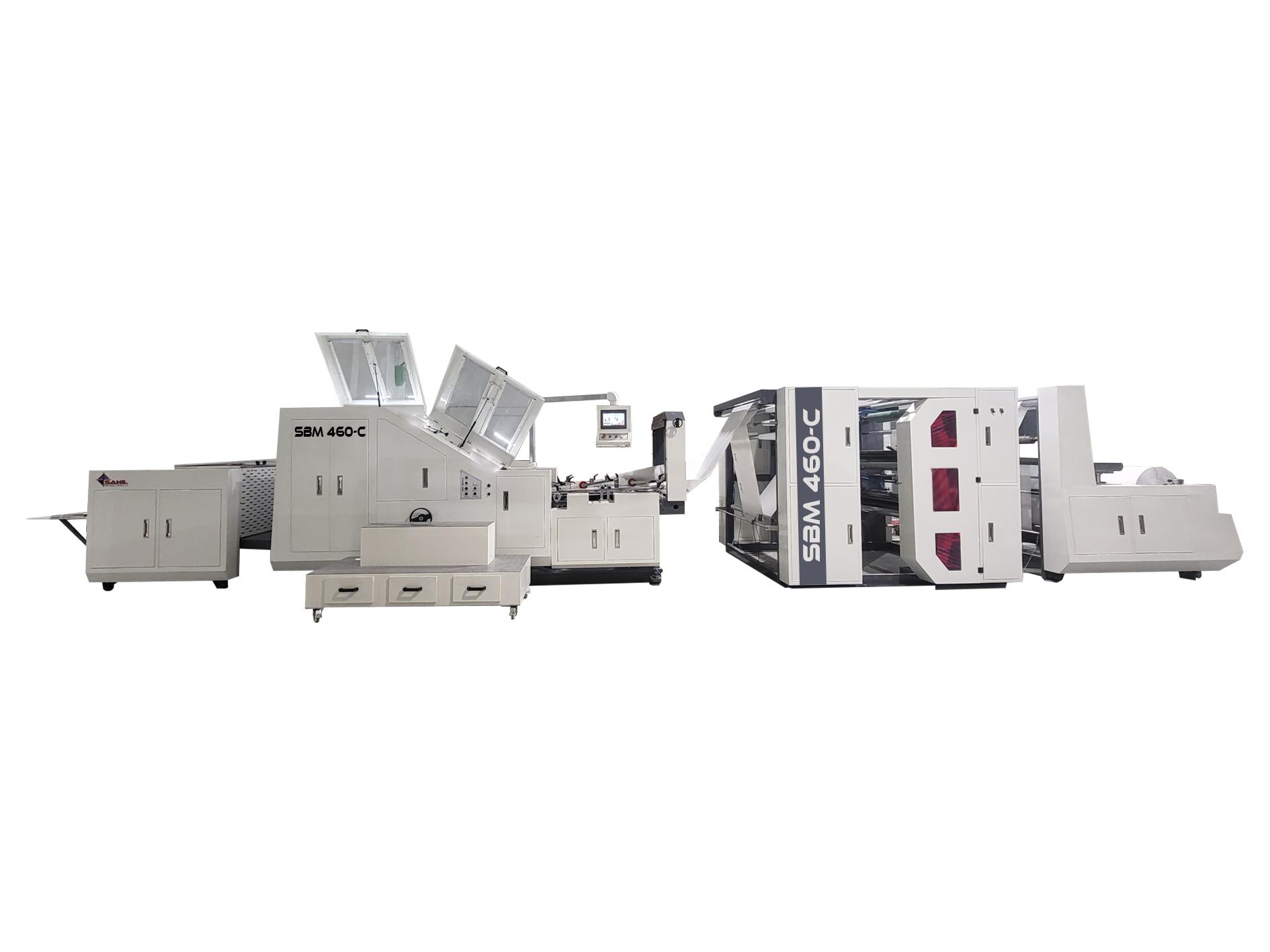

Square Bottom Paper Bag Making Machine With Two Color Online Printing (SBM 460-C)

The Square bottom paper bag making machine design embodies what Sahil Graphics stands for, And features great deal of innovation haven’t seen before. This New Gen of square bottom paper bag making express:

- Widest bag size range

- High Quality Printing

- Durability.

- Performance

- Ease of Operations

- Automation to Reduce wastage

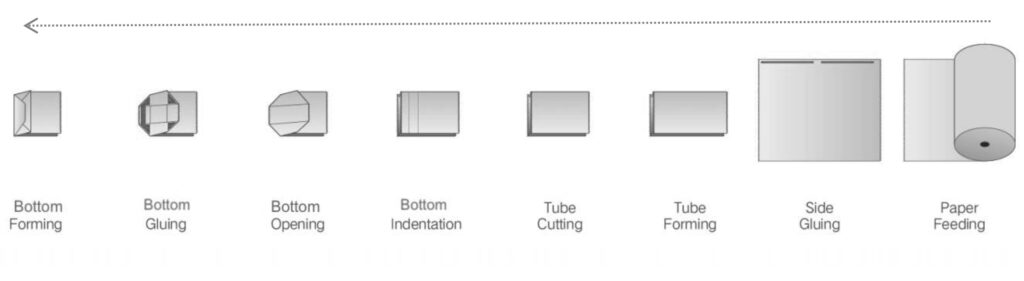

PROCESS FLOW CHART

MACHINE PARTS

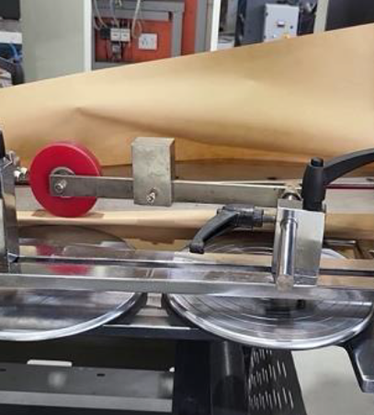

Part 1 Reel Feeding Unit

- Reel feeding is equipped with an automatic hydraulic lifting function, now lifting heavy reels is ways easy and can be done with a push of button

- Unwind using air shaft.

- Heavy Brakes ensure great tension when required.

- Automatic tension control system provides appropriate tension to the paper in the entire reel cycle.

2. Machine is equipped with automatic edge correction system, which help tube formation greatly and reduce wastage.

3. Automatic side glue dispensing system provides exact amount of glue required with respect of different quality of paper. It also ensures, dispensing exact amount of glue required with the speed of running paper.

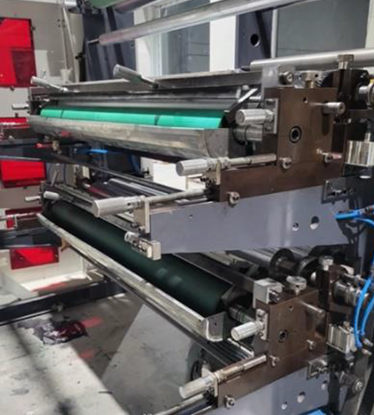

Part 2 Printing unit

This is second part of the machine where the plain paper gets printed.

- The printing unit is equipped with high quality anilox to provide high quality of printing.

- Double nip attachment provides close loop of printing which make registration sharp.

- Long travel in compact design ensures quick dry of printing ink.

- Doctor blades assembly restrict excess ink to the paper, result sharp image formation.

Part 3 Paper bag forming unit

- This is this the unit where maximum operations is executed, starting with: Tube forming Side pasting Bag creasing Bottom opening Bottom Gluing Bottom closing

- Former unit has two servo motor which ensure right cutting. The cutting height can be changed automatically with the touch screen.

- The mechanical component used in former is high in quality which provides smooth performance with great stability

- The machine structure is heavy duty ensures high durability of machine working round the clock

- Auto detection electric sensors has been installed in the former unit which reduces breakdown

Machine Material

| Tube former material | Stainless steel |

| Shaft material | EN 8 hard chromed |

| CAMS materials | EN24 , EN31 |

| Roller | Anodized aluminum , stainless steel |

| Cutter roller assembly | Dynamically balanced |

| Central drum | Dynamically balanced with hard chromed |

| Lubrication | Centralized automatic cooling |

Part 4 Finished bag collection unit

The formed paper bags are pressed and conveyed out of the belt. The bag collecting unit receive the data from plc and can stack bag produced in desired quantity.

- Automatic detection of electric eyes

- Automatic counting photo eye

Part 5 Machine Electrical panel

The electrical panel of the machine can be named the brain of the machine in simple terms. It is equipped with best in class quality of components to deliver seamless work performance. It is also equipped safety devices which safeguards the machine from easily being damage. Component used in the machine are as follows. Automatic fault detection function

This function is mainly used when the machine is running in a normal high-speed state, if an unexpected situation occurs, the machine can be automatically stopped immediately to avoid unnecessary losses. This device is used in conjunction with the Japanese Yaskawa automation control system.

2. Automatic refueling system The system is mainly to automatically supply oil to the machine when it is running, to ensure that the gears of all parts of the machine are well lubricated, so that the machine can exert better performance under long-term operation

Part 6 Component coatings

- The thickness of the shaft Hard chrome plating layer < .1 mm

Part 7 Others

| Fastening screw materials | UNBRAKO (USA) |

| Conveyor belt material | PTG |

| Bearing | SKF (Switzerland) |

| Pneumatic components | JANATICS |

Machine Advantages

Widest Bag Size Range: The Machine Design give you highest freedom of bag size range in its class. With the latest design structure, now you don’t have to buy two different size machines to complete your bag size range.

Hydraulic lift: Material loading adopts hydraulic automatic lifting structure. The unwinding device adopts automatic tension control.

Printing unit with doctor blades: the printing unit is equipped with high quality anilox to provide high quality of printing. Double nip attachment provides close loop of printing which make registration sharp.

Servo Motor control system: The electronic control system imported from Japan is adopted to ensure stable and high-speed operation. Two Servo Motor is used to ensure high accuracy in tube cutting.

Automatic Glue Dispensing: The automatic glue dispensing unit helps you to provide appropriate amount of glue according to the quality of paper. It changes dispensing speed with the flow speed of paper. Improves the quality of bag.

Dual Plate technology: The forming template adopts symmetrical adjustable double template structure so that users of different sizes of paper bags no longer need to change the template, which can effectively reduce the time of paper bag size adjustment and increase the machine capacity.

Automatic Web Guide: Material unwinding adopts automatic correction to reduce material alignment time.

High Quality Materials: Components use in the machine are high quality material which gives immediate confidence of the built quality of the machine.

Connect Now!

Machine Specifications

| S no | Model | SBM 460-C | ||

|---|---|---|---|---|

| 1 | Cutting Length | 270-530mm | ||

| 2 | Paper Bag Width | 230-450mm | ||

| 3 | Bottom Width | 100-200mm | ||

| 4 | Paper Bag Thickness | 60-150g/m2 | ||

| 5 | Paper Bag Speed | 30-200pcs/min | ||

| 6 | Paper Roll Width | 690-1300mm | ||

| 7 | Paper Diameter | 1300mm | ||

| 8 | Inner Diameter of Paper | 76mm | ||

| 9 | Power (3 Phase) | 18.5kw | ||

| 10 | Weight (Approx.) | 10000kg | ||

| 11 | Dimensions (Approx.) | 12000*3800*2200mm | ||

| 12 | Max Width of Printing Material | 1300mm | ||

| 13 | Max Printing Width | 1250mm | ||

| 14 | Print Repeat Range | 191-1000mm | ||

| 15 | Printing Speed | 5-50m/min. Approx. | ||

| 16 | Printing Option | 2 & 4 Colour | ||

| 17 | Anilox Roller | 2 Pcs. / 4 Pcs | = |